Scientists are trying to toughen up the shell of Maine’s soft summertime lobsters, hoping to help the industry fetch higher prices and ship to distant markets.

The University of Maine and Ready Seafood Co. of Portland are joining forces to examine what influences shell growth in Maine’s signature product to see if they can speed up the shell-hardening process in recently molted lobsters.

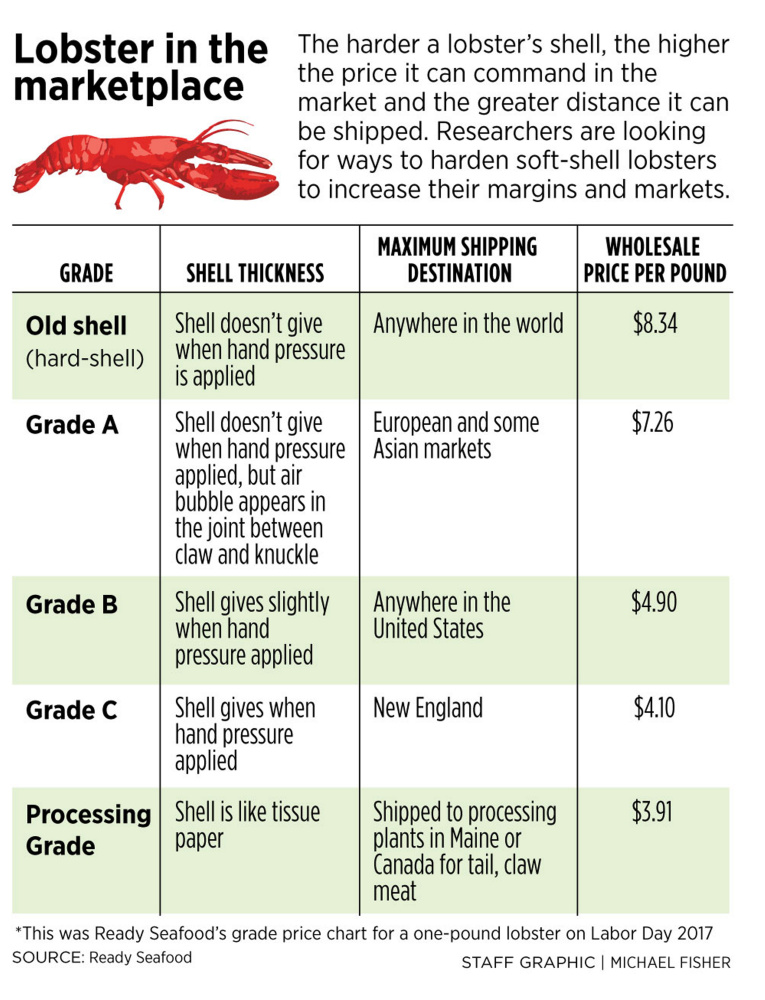

In Maine, the summer catch is mostly soft-shell lobsters, or shedders, which sell for a lower price per pound than a hard-shell lobster. The majority of the summer lobster catch is sold to the domestic market because their fragile shells can’t withstand shipping long distances. Hardening the shell just a little could turn a shedder into a more valuable lobster, regardless of its final market, as well as one that can survive a plane trip to Europe, said Curt Brown, a Ready Seafood scientist.

That is especially important now that a new trade deal has eliminated an 8 percent tariff on Canadian lobsters sold to Europe, a $293 million-a-year market for live lobster. Maine lobstermen acknowledge that their Canadian counterparts dominate the supply of hard-shell lobster in the winter, when that country’s six-month lobster fishery hits its stride.

But in the summer, when Maine’s lobster industry is at full tilt and Canadian lobsters are marking time in holding tanks, the dynamic changes. Even with a tariff, Maine lobsters that can survive the trip to Europe would still be cheaper for European buyers than Canadian hard-shells plucked from long-term storage.

Ready Seafood believes that toughening up a shedder could be Maine’s key to hanging on to or even expanding its summer share of the European market.

“We need to make hay when the sun shines,” said owner Brendan Ready. “From December to June, we will be at a severe disadvantage in this market so we better take advantage of July to November. We must prepare for leaner years and find ways to maximize the resource. … We work on small margins. Canadians are moving forward. We cannot stand still.”

LOBSTERS IN THE LAB

Lobster science has generally focused more on shell conditions during the molting process than the hardening that takes place months afterward. A lobster sheds its old shell and replaces it with a new one to make room for growth. This happens up to five times a year when a lobster is young, but only once or twice a year after a lobster reaches market size, at about 6 or 7 years of age. Females may delay molting in a year when they are pregnant.

Many factors play a role in molting, including water temperature and salinity, availability of food, water depth, the makeup of the ocean bottom and availability of burrows to provide safe shelter in the post-molting period, when a lobster’s shell is tissue-paper thin and makes them vulnerable to attack. Most scientific research conducted on shells has focused on how lobsters avoid microbial attack to fend off shell disease, not on hardening.

Ready Seafood joined forces with the University of Maine to focus on shell hardening in the months after molting, when the lobsters can be sold and shipped to places other than Canadian processors. The softest of all lobsters are known as process-grade, and are sold to processors that pluck their claw and tail meat out for use in lobster rolls and prepared foods. Process-grade lobster fetches the lowest price per pound of any lobster.

Ready and the University of Maine wanted to see if they could find a way to upgrade midrange shedders, or a Grade B lobster, into a firmer shell Grade A lobster. Getting rid of the slight give in the shell that separates a B from an A would have added another $2.36 a pound in value to about 30 percent of the lobsters that Ready sold over Labor Day and expanded the potential market to Europe, Brown said. Harder shells fetch a higher price because buyers get more meat and less water in the lobsters, and because the lobsters have a greater chance of surviving the rigors of shipping and storing.

Maine has a history of storing lobsters landed over the summer in pounds, or outdoor storage tanks, but they are holding the lobsters for months at a time until low supply or high demand says the time is right to sell; they aren’t being stored to grow their shells or improve their grade. This may happen naturally as a result of impounding, but so too does high illness, mortality and product damage, especially to the soft-shells stored there. Canada stores for months at a time, too, but only hard-shells.

STUDYING THE JUMP FROM GRADE B TO A

Brown worked with Abby Shaughnessy, a senior at the University of Maine’s School of Marine Sciences, to see if they could grow 1-pound soft-shell Ready lobsters from an initial Grade B shell hardness into a firmer Grade A in a series of one-week trials conducted over the summer at Darling Marine Center in Walpole, a village in South Bristol. They wanted to know how many would move from one grade to another, how many would get sick or die in captivity and if there was anything they could do to speed up the growth or stave off mortality.

“We couldn’t find anybody else who has tried to do this, so we figured, let’s do it, we should try it,” said Shaughnessy, a 21-year-old from Connecticut who conducted the experiments as part of her honors thesis. “Our goal was to find out if we could improve the lobsters, make them more valuable and hard enough to go overseas, and how fast we could do that without losing too many of them. And if we could hurry that up, that would be great.”

Every week, Shaughnessy would submerge a new group of 48 1-pound lobsters with Grade B shells in holding tanks at Darling Marine Center. She would expose the lobsters to different kinds of environmental conditions. At the end of the week, she would check to see how many had survived a week in storage, evaluate their health through blood and behavioral tests, and find out how many had hardened their shell enough to be sold as a Grade A lobster.

She also looked for patterns, such as how gender, diet, water temperature or storage conditions affected health, mortality and shell growth.

In a typical week, about 35 percent of the test lobsters successfully made the “jump” from a B to an A, which showed that even a short time in a holding tank could help a wholesale company like Ready add value to some soft-shell lobsters and increase how many could be safely shipped to Europe. But tests also revealed that, on average, one B grade out of 10 would not survive the week, resulting in a loss that would hurt profits and strain relations with European customers.

EXPANDING MARGINS

Armed with data from the first round of trials, Ready and the University of Maine will study whether the financial gain of short-term storage will outweigh the costs, including the operational cost of running a storage facility like the one that Ready already has at Pine Point Road in Scarborough. At first glance, it seems that short-term storage would be worth it at certain times of the year, when the price spread between Grade A and B is significant, Brown said.

Based on Shaughnessy’s initial work, Ready could have earned another $2.18 a pound by holding 10 Grade B lobsters for a week around Labor Day – growing three into an A, which would be a $7.08 gain, and conceding the one Grade B loss, which would cost them $4.90. The gain grows when applied to the more than 300,000 lobsters – about 30 percent of which are B grade – that Ready handles in a typical week in late August.

After all that math, Ready could have earned an extra $31,500 from storing a week’s worth of lobster in the run-up to Labor Day, traditionally a big weekend for lobster.

That doesn’t seem like much, but as Ready notes, lobster dealers work on small margins, and anything he can do to add a little more value to the product and hedge against losses that he can’t control, like weather or international trade, will not only help Ready Seafood, but the industry as a whole, which last year saw record-breaking catch and overall value.

But Ready has to offset that sales gain by what it costs to run its holding facility in order to determine the true profit from a week’s storage, Brown said. Right now, Ready keeps the lights on and the water pumping at its holding tank facility even without an active upgrade campaign, but those costs need to be factored in to determine a true benefit. Any adjustment to increase the percentage of lobsters that grow a grade or survive storage would only help expand that thin profit margin.

But so far, the tests do not reveal any shortcuts – neither diet nor water temperature appears to hasten growth or improve survival, Shaughnessy said.

“We found that time is the only factor,” Shaughnessy said. “We couldn’t speed it up, but we proved upgrading could be done for more than a third of those we tested.”

PLAYING THE SHELL GAME

Brown and Shaughnessy’s honors adviser, professor Rick Wahle, hope to continue the work at Ready’s holding tank facility, where trials can be extended to two or three weeks or more and temperature can be more closely monitored, with grants from the National Oceanic and Atmospheric Administration and Maine Technology Institute. The University of Maine believes the project could have far-reaching consequences for Maine’s $533 million-a-year lobster industry.

“That’s the really exciting thing about Abby’s work,” Wahle said. “It’s a college senior’s thesis project, and it’s preliminary results, but if we could figure out a way to make the lobsters we have more valuable, that’s really big for Maine.”

Shaughnessy’s thesis work focused on upgrading B’s to A’s, but in time, Brown would like to try growing A’s into hard-shells that can be shipped to China, which scooped up $84.4 million worth of live American lobsters in 2016. About 83 percent of U.S. lobsters shipped abroad are sold out of Maine. While American lobster exporters are getting “shellacked” by the EU tariff differential with Canada, Brown said, both countries are benefiting from a tariff reduction on imported lobster to China.

Eventually, Brown would like to see if Ready could hold back at least a portion of its summertime catch for sale when peak landings subside and global demand begins to outpace supply and drive low summertime prices back up. This is what traditional Maine lobster pounds have been doing for years, hoping demand is high enough to get prices that can offset high mortality rates, and what Canadian dealers do when they “condo,” or store, their hard-shell winter bounty in individual holding cells.

But for now, Brown is happy with the low mortality rates he’s getting with Maine soft-shells while playing a literal shell game that he hopes will eventually benefit others.

“A big part of it for us is to move our whole industry forward, not just our company,” Brown said. “We started as lobstermen and we feel that the real test of whether this work will be considered a success is whether or not it translates into a benefit for other harvesters, whether through increased boat prices or lobstermen and women using similar methods to improve the quality of their own catch.”

Penelope Overton can be contacted at 791-6463 or at:

poverton@pressherald.com

Twitter: PLOvertonPPH

Send questions/comments to the editors.