FARMINGTON — The University of Maine at Farmington is proposing to build an $11 million wood chip-fueled heating plant, which will reduce the school’s carbon footprint and close the door to a natural gas pipeline to the town in the foreseeable future.

The project was approved Monday by the University of Maine System board of trustees.

UMF originally announced it would pursue a contract with Summit Natural Gas of Maine Inc. for natural gas as an energy source, but after the company announced multiple delays in its proposed construction schedule that meant the pipeline wouldn’t be built until 2016, university leadership said the school could not wait and went back to looking at other energy.

Earlier this month, Summit spokeswoman Julie Rowey said in a written statement that Farmington isn’t in the company’s construction plans. Summit had previously said that if UMF, Franklin County’s largest energy consumer, wasn’t going to be part of the pipeline network, it wouldn’t extend to Farmington.

The new plan for UMF’s energy future is designed to reduce its dependence on oil and increase its use of renewable fuel sources.

“Consumption of 95 percent of the fossil fuel will be eliminated,” said Mark Power, team leader from Trane Inc., a climate engineering and construction firm that is contracted to build the energy system.

Members of the UMF Central Heat Plant Building Committee said Thursday that the heating system is projected to recoup its construction costs through energy savings in 10 years.

Farmington officials and business leaders had hoped a natural gas pipeline would extend to the town to lower the cost of living and doing business.

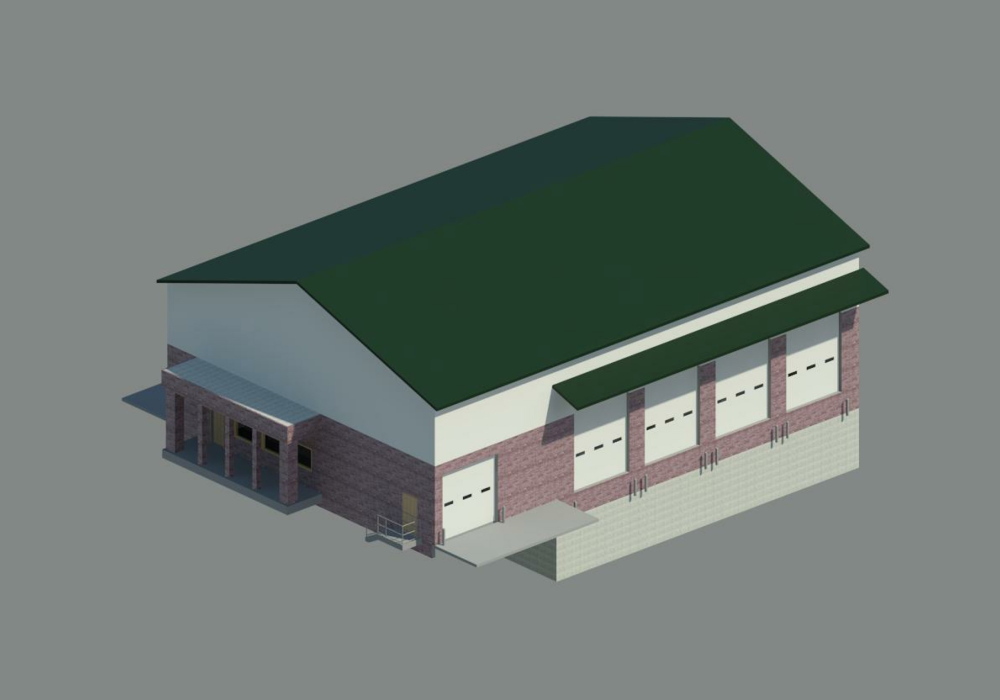

UMF’s proposed 5,885-square-foot central heating plant is projected to be built on the site of a university parking lot near the corner of Perkins and Quebec streets.

Power said the building will be designed with a brick exterior to match other campus buildings and will have room for a second boiler if the university needs to expand in the future.

The boilers have a life expectancy of about 40 years, he said.

Jeff McKay, director of facilities management for UMF, said the heating plant also would be a teaching tool for students to learn about the sustainable energy source.

“It would be a place where you could bring classes to do tours,” he said.

The boiler will heat the campus with hot water, which would circulate through closed loop piping.

UMF has offered to add one of Farmington’s municipal buildings to the heating system.

Town Manager Richard Davis said previously that the selectmen are considering the option, which could lead to long-term savings.

If the town converts the Farmington Community Center building to be heated by the UMF heating plant, it will cost about $90,000 to connect to the plant, but the cost to the town is expected to be paid back in an estimated 7.6 years, after which the conversion will save the town money on heating.

The Farmington Community Center uses about 6,750 gallons of heating oil annually.

The Farmington Planning Board needs to review and approve construction of the building.

Project managers are expected to make a presentation on the heating plant at a board meeting at 6 p.m. on Feb. 9. A vote to approve the project could come March 9.

Project planners expect to have final pricing for the project by March 15, with groundbreaking by May 1, and the start of construction no later than June 1, according to Tom Perkins, of Dirigo Architectural, which is overseeing the project for UMF.

He said construction should be substantially completed before students return Sept. 15.

The UMF Sustainable Campus Coalition coalition has a long-term goal of UMF having a zero net impact on greenhouse gas emissions by 2035.

The university’s first target is to have a 20 percent reduction in greenhouse gas emissions this year compared with 2007 levels.

Send questions/comments to the editors.